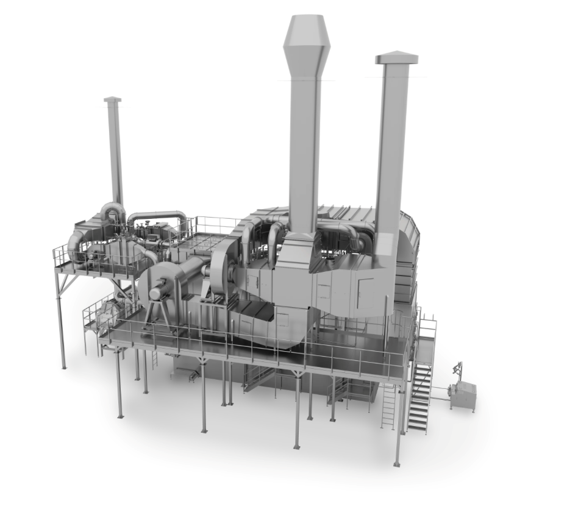

Specht is a manufacturer of poultry farming technologies with a tradition dating back to 1961. The company offers a wide range of products for rearing pullets and keeping laying hens, including cage and aviary systems as well as laying nests—all fully made in Germany.

Our professional staff will respect your requirements and are happy to advise you on selecting the right installations. This can include rearing chicks or laying hens in floor, aviary, or group housing systems. We take an individual approach to each customer and are pleased to demonstrate model installations, provide on-site services and consulting, and even offer visits to installations at other farms so you can see how the equipment works in practice.